- Home

- >

- Products

- >

- 5G radome antenna

- >

5G radome antenna

1. The 5G antenna cover ensures that the antenna meets the performance of 5G electrical appliances, and also has the advantages of high precision, high integration, flexible processing, and light weight;

2. The plastic antenna vibrator is made of modified plastic materials containing organic metal compounds, and is manufactured by injection molding;

3. Material: ABS-HB white YB816 swan white

4. The nozzle is cut smoothly, without peaks, stains, top white deformation, uneven glue running, water lines, flow marks, burnt, shrinkage, dragging, and yellowing;

5. The product complies with the "Access Network Fixed Terminal WLAN Antenna Acceptance Specification";

6. The materials and processing technology used should meet the environmental requirements of <

7. The appearance quality of the antenna is in accordance with "DKBA0.400.0213 REV.B Terminal Product Appearance Quality Requirements";,

8. The quality requirements of raw materials are in accordance with "DKBA04000112 Quality Requirements for Non-metallic Materials";

9. The raw materials and manufacture of this product must comply with QW-Q-043 environmental substances;

- Information

1. In terms of radome, it has good electromagnetic wave penetration characteristics, strong mechanical properties that can withstand harsh environments, and can be insulated, anti-corrosion, and lightning-proof;

2. Under the 5G trend, superior performance has become a popular antenna cover;

3. The material can play the role of insulation, anti-corrosion, lightning protection, anti-interference, durability, etc., and the effect of wave penetration is very good;

3. In terms of the shell of the base station, the traditional 4G base station is in the shape of a large iron tower, while the 5G base station is characterized by small size and light weight, so it can also be made of composite materials. Composite materials have the advantages of easy processing, powerful performance, and light weight;

4. Lihong is a company engaged in the design and manufacture of precision molds and precision injection molding products for many years. The company focuses on providing complete solutions for brand owners from product design, precision mold manufacturing, injection molding and assembly, and after-sales service;

5. Plastic injection molding processing, professional manufacturer, quality assurance, high product qualification rate, can be customized according to customer needs, welcome to call to discuss cooperation and negotiation.

6. The fixed seat and the pole sleeve are rotated to the position of 30 degrees, and the counterweight 40G on the top of the pole sleeve can be stuck in the groove (the position of 30 degrees is the position in the middle of the 3 angles of rotation);

7. Fix the fixing seat, apply a pulling force of 5kgf to the rod sleeve for 2S, repeat 20 times, apply a pulling force of 5kgf to the fixing seat for 2S, repeat 20 times, and there is no obvious damage or fall off;

8. After the rubber plug and the rod sleeve are assembled, the pulling force is 3kgf without loosening, and the rod sleeve is fixed, and the rubber plug is not loosened and detached by using cables or wires, and the insertion force is less than 1.5kgf;

9. Meet relevant reliability tests such as bending durability tests;

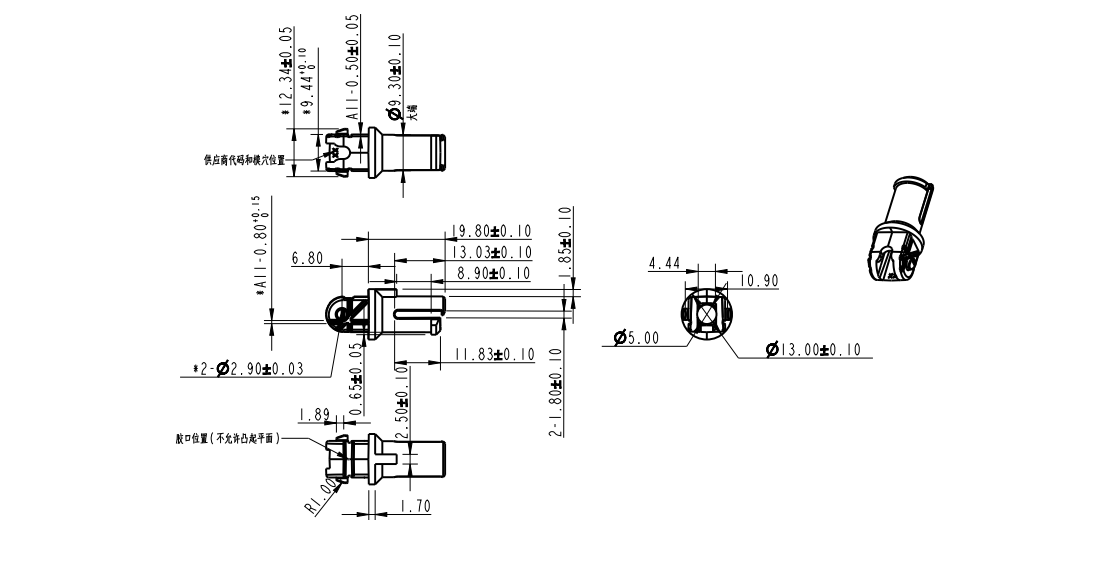

The product drawings are as follows: