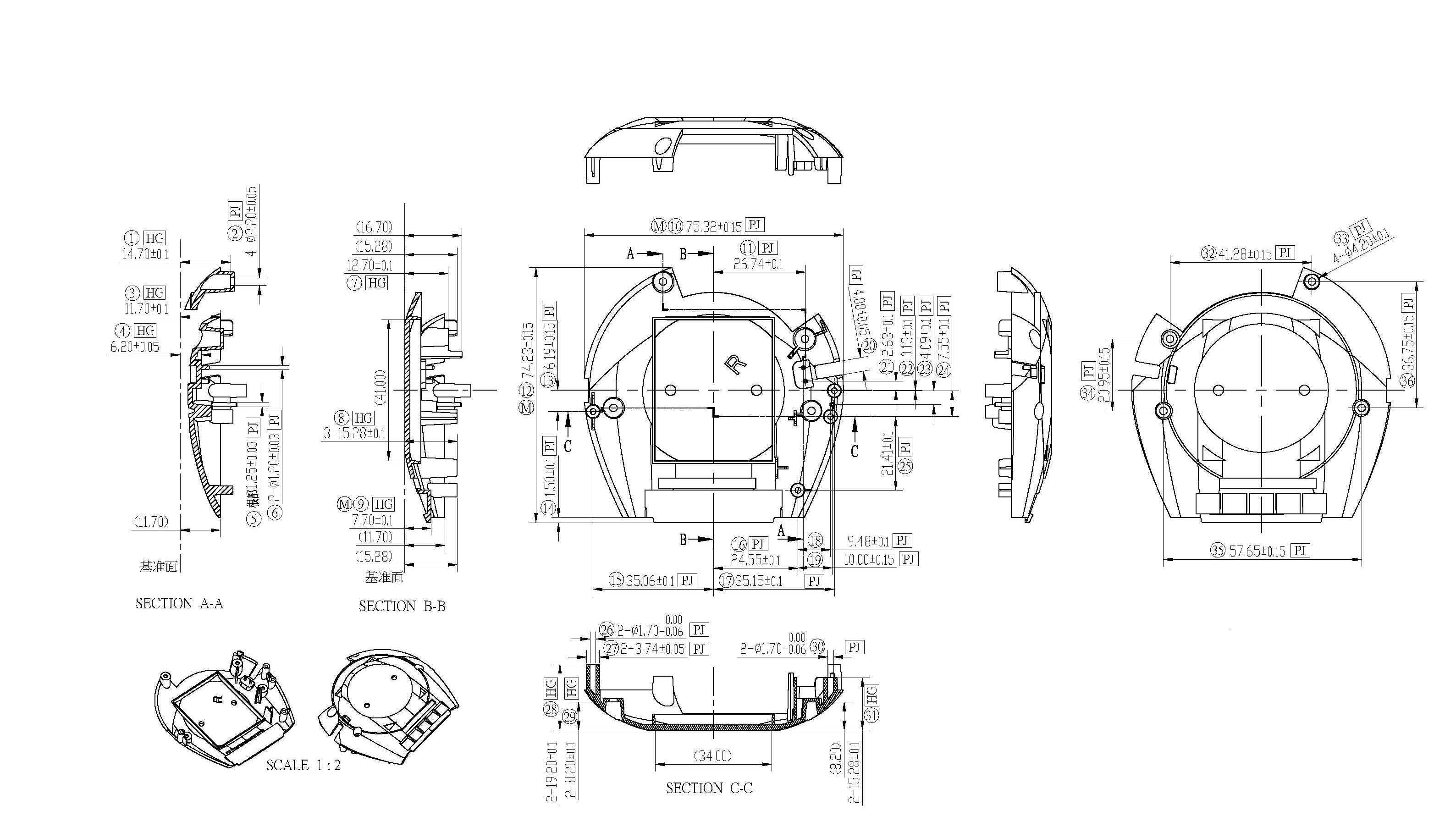

Headphone injection molding

1. Features of plastic headphones/audio: anti-slip, anti-shock, anti-scratch, anti-drop, wear-resistant, distinctive personality, cool, enhanced service life, beautiful;

2. The materials mainly include PP, PC, ABS, etc. The strength of the material, good toughness and easy processing and molding, good chemical stability, good electrical properties, can be chrome-plated, painted, high impact resistance, high heat resistance, flame retardant , enhanced, transparent and other features;

3. The nozzle is cut smoothly, without peaks, stains, top white deformation, uneven glue running, water lines, flow marks, burnt, shrinkage, dragging, and yellowing;

5. The product complies with the "Access Network Fixed Terminal WLAN Antenna Acceptance Specification";

6. The materials and processing technology used should meet the environmental requirements of <

7. Appearance quality is in accordance with "DKBA0.400.0213 REV.B Appearance Quality Requirements for Terminal Products";,

8. The quality requirements of raw materials are in accordance with "DKBA04000112 Quality Requirements for Non-metallic Materials";

9. The use of raw materials and production of this product must comply with QW-Q-043 environmental substances;

- Information

1. The appearance of the product is burr, the breakage is controlled within 0.05, no top white, shrinkage, oil stains and other poor appearance;

2. The material of the product is PC+ABS C1200. Black;

3. The product has been bent at room temperature (bending angle at room temperature is 270°) and at low temperature (temperature -10°C, manual bending at 180° for two hours);

5. The silk screen position of the product appearance has passed the friction test (use a white cloth (100% pure cotton) soaked in alcohol with a concentration of 98% and wipe it 20 times with a force of 500g), there is no printing on the tape after the test, and the decorative inlay does not fall off;

6. Lihong is a company that has been engaged in the design and manufacture of precision molds and precision injection molding products for many years. The company focuses on providing brand owners with a complete set of solutions from product design, precision mold manufacturing, injection molding and assembly, and after-sales service;

7. Plastic injection molding processing, professional manufacturer, quality assurance, high product pass rate, can be customized according to customer needs, welcome to call to discuss cooperation and negotiation.

Product Size: